Bottle Closures and

Cap Liners Guide

Choosing the right bottle closure or cap liner is essential to product performance, safety, and shelf appeal. From dispensing functionality to protective liners and brand aesthetics, every detail matters. Pipeline Packaging’s Bottle Closures and Cap Liners Guide helps you explore available styles, materials, and liner options—making it easy to find the perfect match for your product.

Scroll through the different styles and functions of closures and caps, helping you understand which design best suits your product’s branding, dispensing method, and protective needs.

Next, it dives into the world of cap liner materials, explaining how various options offer moisture barriers, chemical resistance, tamper evidence, and more to ensure the perfect seal and compatibility with your product.

Cap Types

Choosing the right closure is critical to your packaging’s performance and presentation. From enhancing shelf appeal and reinforcing your brand to ensuring secure dispensing and product integrity, closures do more than just seal a container. At Pipeline Packaging, our experts help you navigate the many options to find the ideal bottle and cap combination, ensuring compatibility, protection, and a seamless customer experience.

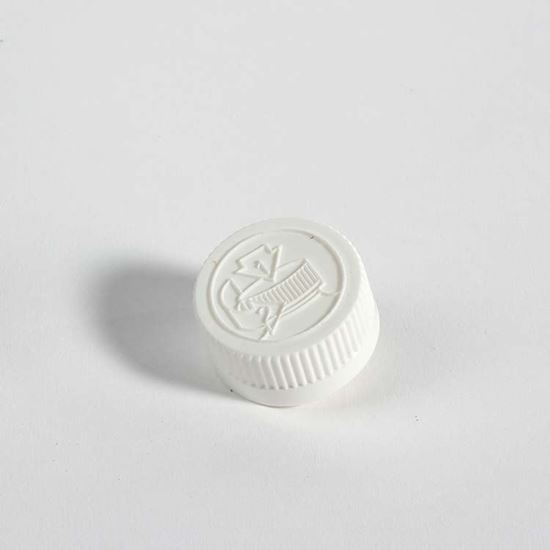

Threaded Caps

This closure has spiral threads to match the top of the container. The threaded cap twists onto the neck and closes the appropriate object. It is a customizable piece that can fit what is required.

Lug Cap

One of the most popular metal closures in the world. The lug cap comes in either a flat or button top. The button top releases pressure in the container if opened which creates a longer shelf life for the product. This closure if opened by a small counterclockwise turn.

Child Resistant Caps (CR)

These closures are required for certain objects. For example, most over the counter drugs. A person must press down and then twist counterclockwise to open it. This makes it difficult for a child to open, while not making it difficult for adults to use. CR closures come in many different sizes and shapes.

Snap Caps

A closure that works very well for food and/or beauty application products. The cap snaps into place on a ridge that is lifted or concaved. The closure will come off completely, which allows the product to flow out smoothly. Once closed, the product is securely sealed inside the container.

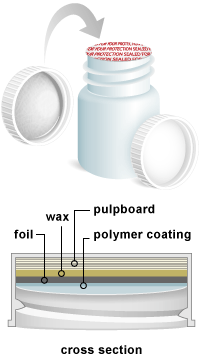

Induction Lined Caps

Induction liners have multiple layers: foil, pulpboard, wax, and a polymer coating. The layers create a hermetic seal after going through an induction machine, during which the heated foil melts both wax and polymer. Induction-lined caps require an induction sealing machine to be applied. If the liners are off, the product has been tampered with.

Brush Caps

This closure is unique, due to the brush attached to the cap. The cap has grooves in it to tighten on the top of the container. The brush is used for the precision spreading of a product. The cap seals the product securely, so it doesn’t dry out.

Dispensing Caps

The right dispensing cap can improve the user's experience immensely. Dispensers are often used for health and beauty, handsoaps, and medical packaging and can be a convenient, easy-to-use packaging option that has a long lifespan. Below are dispensing cap options and descriptions currently available for purchase at Pipeline.

Flip Top Spout Caps

To release the liquid within the bottle, users need to flip the small dispensing opening to an upright position. To close, a small push downward seals the cap and makes it level with the cap to prevent leakage.

Pumps

Pumps enable consumers to distribute an even film of highly viscous products, such as lotion to an object. Push down on the top of the pump to dispense the product.

Sprayers

This closure applies a balanced amount of product to a surface. The two types of sprayers available are trigger and pushdown. Pulling the trigger or applying pressure down on the pushdown sprays the product.

Push/Pull Caps

Push/Pull Caps are those most commonly found on dishwashing detergent bottles. Pulling the cap upward creates an opening for the product to dispense. After use, a simple downward push on the cap itself closes it.

Twist Top Caps

This closure opens and closes through a twisting motion. Turning the cap counter-clockwise opens the closure, while turning clockwise seals it. These caps are very common with condiments.

Glass Dropper Caps

The cap is a rubber bulb, found at the top of the dropper. Applying and discharging pressure to the cap will pull liquid into the dropper. Once full, applying pressure to the cap allows the product to be placed in a precise location, one drop at a time.

Snap Top Caps

A hinge is connected to the top and bottom of the closure. Once the top is lifted, the closure has a small opening in the middle. This allows the product to be distributed. The top can be snapped back in place to securely close the container. These closures are great for food condiments and toiletries items.

Dropper Caps & Plugs

The dropper cap’s plug is created to decrease the size of the bottle’s opening like a small funnel. These plugs come in two different styles: controlled or streaming. The caps are unlined and cover the dropper tips; they then screw into the top of the bottle.

Disc Top Caps

Delivering pressure to the closure, on the end often labeled “press”, will pop the opening and allow the product to flow out. Pressing down on the opposite end of the cap will push the opening back down. This seals the container from distributing the product. The closure is designed to stay on the container throughout the product's life cycle.

Choosing Liner Types

Selecting the right cap liner is a critical step in ensuring proper packaging performance and product protection. Whether you're packaging food, chemicals, pharmaceuticals, or consumer goods, the liner inside the cap plays a key role in maintaining freshness, preventing leaks, and offering chemical resistance. Some liners act as moisture barriers, while others are designed for tamper evidence or enhanced safety. The liner material you choose can also impact your overall packaging costs. Always test your product with the selected liner to ensure compatibility and performance. Explore the most common types of cap liners below to find the best fit for your application

Liner | Description | Benefits | Disadvantages | Common Uses |

3-Ply Foam (F217) | A three-ply liner is a general-purpose liner, made of compressible polyethylene foam. These do not create a seal and are often used for leak prevention. F217 is a name brand and is often interchangeable with the foam liner. |

|

|

|

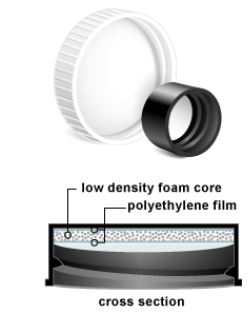

Polyethylene Foam

| General-purpose liner made of compressible polyethylene foam that does not create a seal. Often used to prevent leaking. |

|

|

|

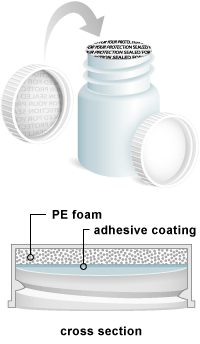

| Pressure Sensitive

| A pressure-sensitive foam liner with one adhesive side that sticks to the container with the pressure used to stick on to the rim of the container. When the closure is removed, the pressure-sensitive liner remains on the top of the container. They are typically white on each side. These can come printed on one side with “Sealed for your protection” or can come unprinted. |

|

|

|

Induction

| They can be made with layers of pulpboard, wax, and foil. These liners are applied to the container with the use of an induction sealing machine. When the liner is heated, the wax melts to the container creating an airtight, hermetic seal. These can come printed with a message (such as sealed for your protection) or plain. |

|

|

|

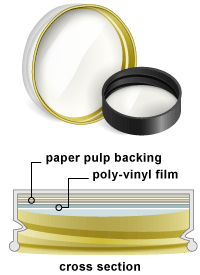

Poly Vinyl

| Liner is made of a thin, vinyl coating applied to high-density polyethylene coated paper that is laminated to pulpboard. |

|

|

|

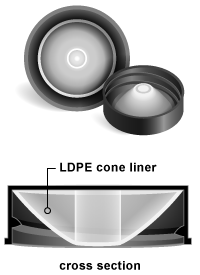

Polyseal

| An LDPE cone liner that creates a wedge type seal across the top of the container providing a leak-proof seal for liquid products, virtually eliminating leakage, evaporation, and contamination. |

|

|

|

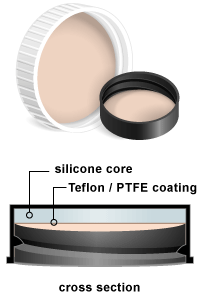

Teflon PTFE

| A Teflon faced liner will maintain the base liner’s sealing properties while adding chemical resistance. |

|

|

|

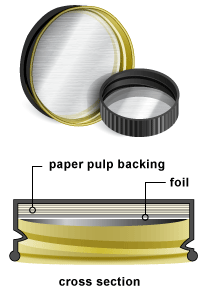

Foil

| A polyester film laminated to aluminum foil and bonded to pulpboard. |

|

|

|

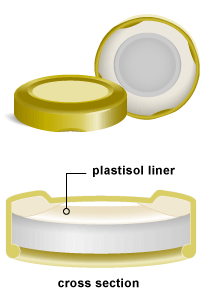

Plastisol

| A plastisol liner is part of a cap. A plastic gasket lines a metal cap, which creates an airtight seal when heated and then cooled. Plastisol liner is effective only when the temperature of the bottle is at 140 degrees when applied to cause the liner to soften and form a hermetic seal around glass containers. |

|

|

.jpeg)

Bottle Closure and Cap Liners Guide

Closures are essential to the success of your packaging, impacting everything from aesthetic appeal and branding to dispensing functionality and product protection. At Pipeline Packaging, our team of experts ensures the perfect match between bottle and cap by testing compatibility and considering every detail tailored to your needs.