Cap and Neck Finishes

Measurement and Compatibility

Finding the right cap and neck finish for your packaging container is crucial. The experts at Pipeline Packaging are here to guide you through common neck finish and container cap options.

Cap and Neck Finishes

Bottle products have a cap, stopper, or container closure that needs a finish. Fortunately, the Pipeline team is here to guide you through standard neck measurements, common GPI/SPI neck finishes, how to measure a neck finish or provide downloadable resources that can with determining the best option for your product.

How to Identify Closure Sizes

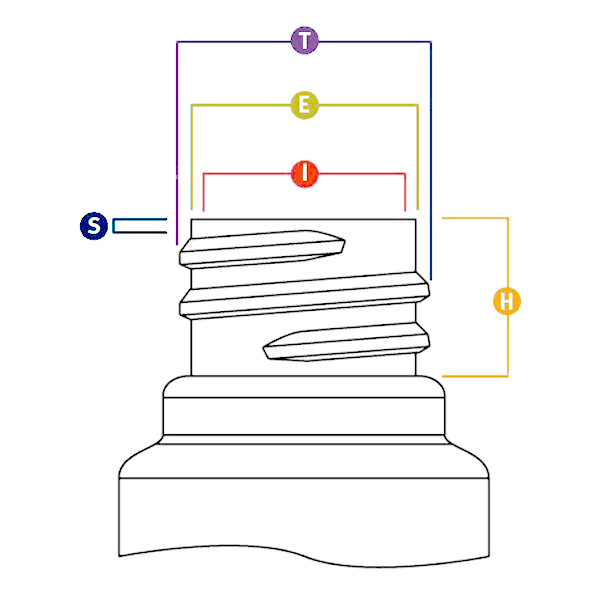

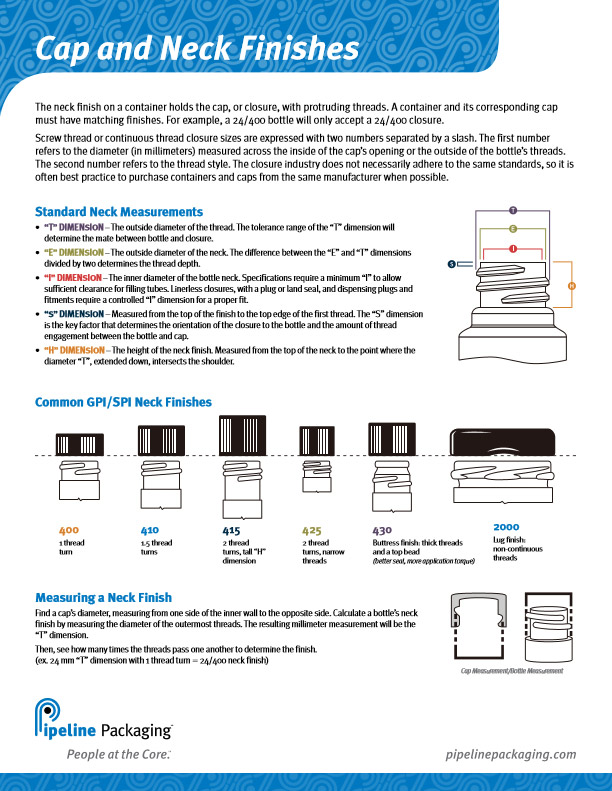

Screw thread caps or continuous thread closure sizes are expressed with two numbers separated by a slash. The first number refers to the diameter (in millimeters) measured across the inside of the cap’s opening or the outside of the bottle’s threads. The second number refers to the thread style. The closure industry does not necessarily adhere to the same standards, so it is often best practice to purchase containers and caps from the same manufacturer when possible.

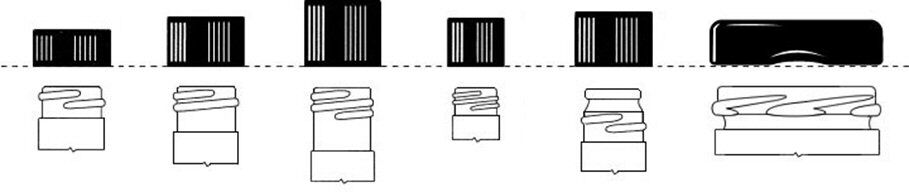

Common GPI/SPI Neck Finishes

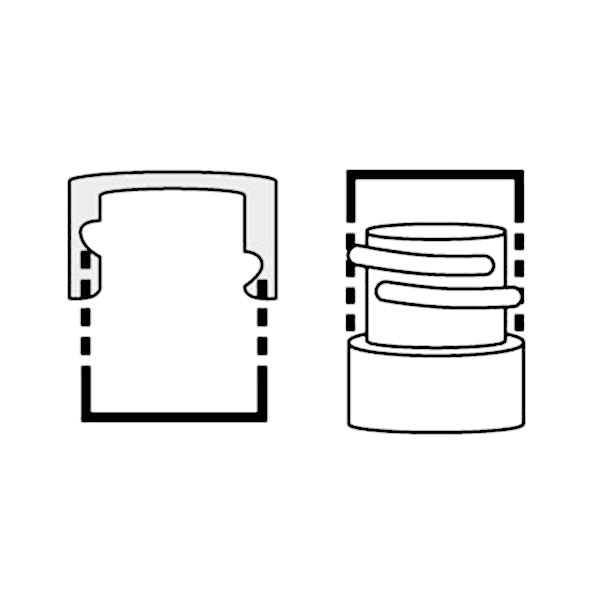

How to Measure a Neck Finish

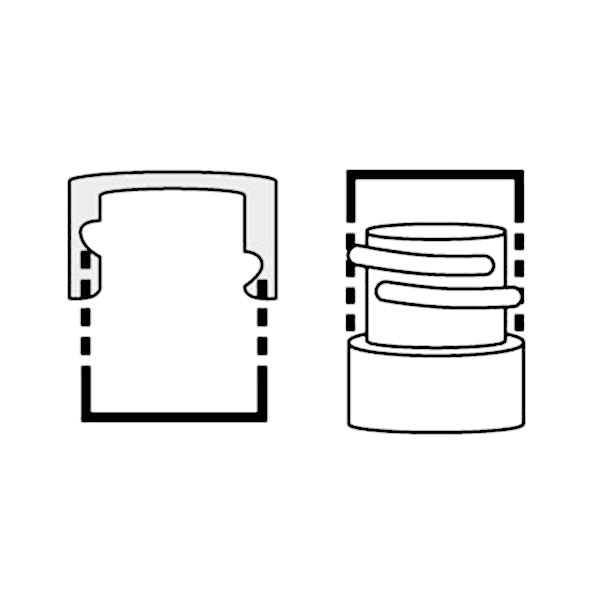

Finding bottle neck finish dimensions is a simple process. Start by measuring from one side of the inner wall to the opposite side. Then, calculate the neck finish by measuring the diameter of the outermost threads. The resulting millimeter measurement will be the “T” dimension.

Then, see how many times the threads pass one another to determine the finish.

(ex. 24 mm “T” dimension with 1 thread turn = 24/400 neck finish)

Related Resources

Cap and Neck Finishes

Please make use of our Cap and Neck Finishes Guide, detailing the standard neck measurements, common neck finishes and how to measure them.