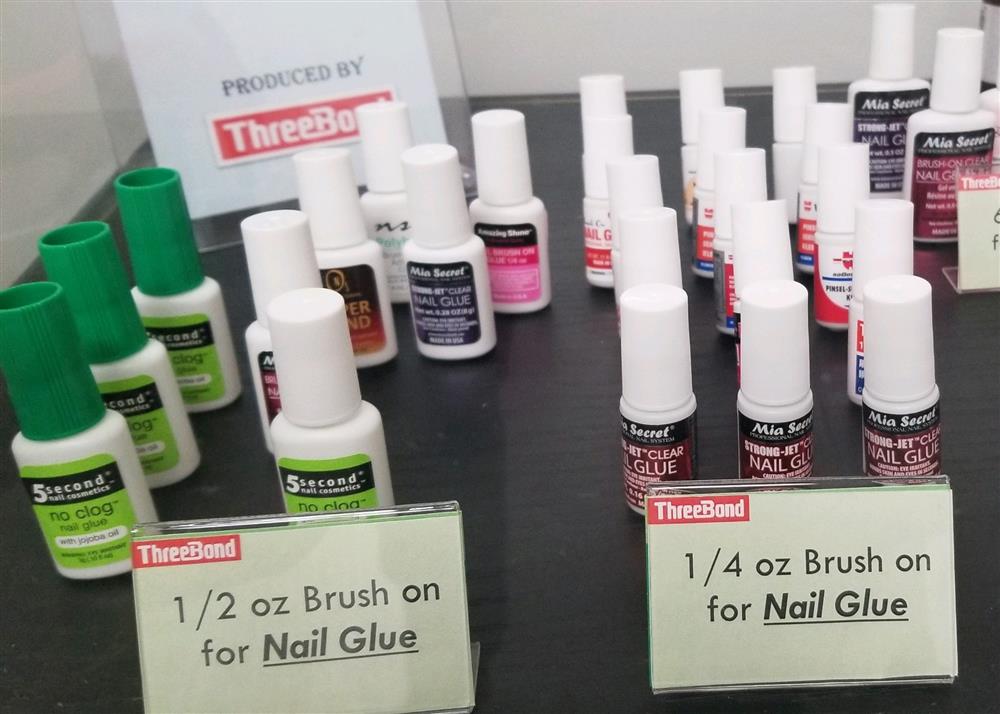

For more than half a century, ThreeBond International has developed a reputation as a global technology champion. The company offers outstanding products and solutions for a variety of markets, which includes more than 45 years of experience as a leading provider of private label nail care goods.

Unfortunately, supplier issues can create problems for any company that’s committed to excellent products and unmatched customer service. That’s why ThreeBond turned to Pipeline Packaging when they needed a packaging partner that could consistently provide quality parts and consistent orders.

The Challenge

The reason why ThreeBond came to Pipeline was simple: The company was experiencing issues with their current supplier regarding injection molded neck inserts used for nail polish application brushes. Unfortunately, there wasn’t just one major issue. Instead, there were a variety of problems that repeatedly frustrated the team at ThreeBond.

The reason why ThreeBond came to Pipeline was simple: The company was experiencing issues with their current supplier regarding injection molded neck inserts used for nail polish application brushes. Unfortunately, there wasn’t just one major issue. Instead, there were a variety of problems that repeatedly frustrated the team at ThreeBond.

The major issue for ThreeBond was that the existing supplier’s mold could not consistently produce quality parts. While molds can last for decades with proper care, the supplier’s mold struggled with part quality due to age and a lack of maintenance. The part failure rate only got worse over time as well. By the time ThreeBond decided to contact Pipeline, roughly a third of the neck inserts produced by this mold were unfit for production.

The poor part quality also posed problems for ThreeBond’s production lines. A bad part might not fit into the nail polish bottles properly, which could jam up production lines. Even if an improper part were to seemingly fit, it may cause leakage or allow air in that would spoil the product. The sheer number of bad parts forced ThreeBond to regularly shut down whole lines for upwards of 30 minutes to conduct 100 percent part inspection. That downtime only added to ThreeBond’s labor and production costs.

In addition to the production problems, ThreeBond grew frustrated with their old supplier’s customer service. The supplier had difficulty fulfilling ThreeBond’s orders and wouldn’t confirm any orders for weeks or months at a time. Even after confirmation, ThreeBond would receive sporadic shipments of partial orders with bad parts. These shipments were also sent from California to ThreeBond’s facility in Ohio, adding extra freight costs to the already inconsistent service.

The Solution

The first step Pipeline took to solve ThreeBond’s challenge was to eliminate the creation of bad parts. To start, Pipeline used its global network of suppliers to have a new mold made in Ohio. This new mold is regularly maintained and ensures that nearly 100 percent of the injection molded neck inserts are made properly.

The first step Pipeline took to solve ThreeBond’s challenge was to eliminate the creation of bad parts. To start, Pipeline used its global network of suppliers to have a new mold made in Ohio. This new mold is regularly maintained and ensures that nearly 100 percent of the injection molded neck inserts are made properly.

Another key part of the project was to centralize and simplify the shipping process. Utilizing an Ohio supplier to manufacture the injection molded parts not only improved the overall production quality, but also drastically cut down on shipping time and freight costs. Now ThreeBond could have their parts manufactured in Northeast Ohio, fluorinated in Columbus, and directly shipped to their main facility outside of Cincinnati. Additionally, Pipeline oversees the entire process, allowing ThreeBond to consolidate their billing for these parts down to a single vendor.

Pipeline also eliminated the issues involving partial order and shipping delays. Our order fulfillment and logistics team provided ThreeBond with regular updates on shipments and made sure that the company had all the parts they needed to keep up with demand.

The Results

With the new mold and improved shipping setup in place, Pipeline has helped ThreeBond increase production efficiencies, eliminate waste, and streamline a key part of their business. There have been no issues with the new custom injection molded neck inserts, which has turned a regular problem with part quality into a nonissue. In addition, ThreeBond has been able to cut shipping costs and time to market thanks to localized, regular products shipments.

Are you looking for a packaging distributor that can help you solve quality and logistics issues? Check out our available packaging products online or contact us today to talk to one of our experts today about your packaging needs.