Pipeline Packaging has been a leading distributor of drum packaging —including steel drums, plastic drums, and fiber drums — and IBC totes, as well as all the necessary accompanying fittings, gaskets, lids, and more for longer than 30 years.

Over those years, Pipeline customers have come to understand that when they need large-volume packaging designed to protect their products, customers, and the environment, Pipeline is a go-to source for drums and totes for food processing to hazardous materials … and everything in between.

When it comes to steel drums and other industrial drum packaging and totes, it’s safe to say Pipeline Packaging doesn’t miss a beat.

40 Years of Experience

While Pipeline Packaging’s collective expertise is quite impressive, one Pipeline sales representative, Randy Allison, has more than four decades of experience dealing with drum packaging and many other industrial packaging solutions for his customers.

Allison worked for a steel drum manufacturer for 26 years. He also worked for two distributors, one of which was acquired by Pipeline Packaging a few years ago.

There are many options when dealing with industrial drums today. It’s safe to say not all drums are created equal.

From the materials they’re manufactured with to the coatings they’re lined with, there are certainly some complexities related to industrial drums. Then there’s making sure the right fittings and gaskets are selected and the proper specifications, such as UN ratings, are achieved.

Keeping It Simple

Allison says the Pipeline team’s understanding of drum packaging, and his own, help to simplify the process for customers.

“It all sounds complicated until you’ve been dealing with it for more than 40 years,” Allison said. “I really enjoy helping our customers determine exactly what drums they need to handle their unique, specific applications.”

It’s a Real Smorgasbord

One advantage Allison sees working for Pipeline Packaging is the breadth of products he’s able to provide to his long-time drum customers.

“It’s great working at Pipeline Packaging because we have a much broader product line than I’ve ever had access to,” said Allison. “It’s the full gamut of packaging. This allows me to offer more solutions to the customers I’ve been working with for many years. They really appreciate that.”

A Multitude of Manufacturing Options

Through our network of more than 300 global suppliers, Pipeline Packaging has access to thousands of industrial packages. Whatever you’re looking for, we can help with your company’s needs.

Our worldwide manufacturing network can quickly and economically source the steel drums, plastic drums, fiber drums, IBC totes, and other packaging you need, right when you need it.

Pipeline offers a full line of new and reconditioned drums, and new, reconditioned, and remanufactured totes.

Highly Rated in Achieving Ratings

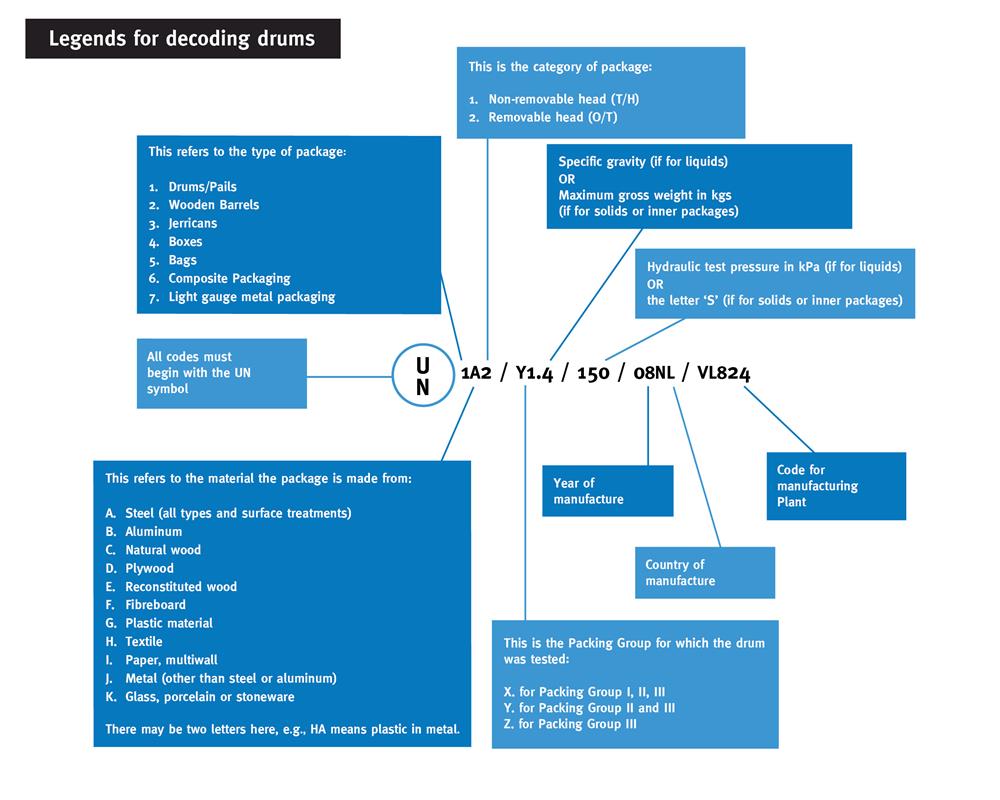

Many customers need to attain a specific UN rating. The Pipeline team understands the ins and outs of packaging and will help ensure that your drum packaging or tote meets the required specifications. The chart below outlines the meaning behind the letters and numbers that make up UN ratings.

Continuing Education

According to Allison, the drum packaging knowledge within Pipeline Packaging is amazing and exciting.

“I learn something new every day,” he said. “And I’m able to teach something new every day, too.”

As he’s continued in his role in drum sales, Allison has seen new, young professionals coming into the industry.

“I enjoy sharing what I’ve learned about drums,” he said. “I’ve been through a lot in this industry, and I’m here to help educate those who don’t have as much experience, whether it’s a customer or a co-worker.”

Risk vs. Reward

It’s important to remember that the filler of the drum is always responsible for compliance and regulation, Allison said. So, Pipeline is always pointing out risk-reward scenarios for its customers.

“One small mistake could be very costly for our customer,” Allison said. “It’s not always about the lowest cost. Our responsibility is finding the drum or tote that’s going to meet the necessary requirements and ratings. Our specialty is minimizing possible risks and maximizing potential rewards for our customers.”

Many times, it can cost a little more to reduce that risk.

“We recommend that customers work closely with their Pipeline sales representative to establish exactly what drum they need for their particular end use.”

A New Day … A New Challenge

For Allison, every day is another adventure.

“Industrial packaging is an interesting business,” said Allison. “And I really enjoy every element of helping my customers navigate it successfully.”

Bang on Our Drum!

Contact us today to learn more about our drum packaging and IBC tote product lines, as well as our associated offerings. Our experienced team of industrial packaging experts looks forward to helping you select the right drum or tote products for you.